Supercharger vs. Turbocharger: Which is Better?

Turbochargers and superchargers are both types of forced induction systems that increase the amount of air an engine can take in, resulting in more power. A turbocharger is a device that intensifications the power output of an engine by compressing the air that enters it. It works by using exhaust fumes to turn a turbine, which in turn energies a compressor that forces more air into the engine. A supercharger, on the other hand, is driven by a belt connected to the engine and compresses the air before it enters the engine. Both systems have their advantages and disadvantages, but they both provide a significant boost in performance for internal combustion engines.

What Is a Turbocharger?

A turbocharger is an engine component that boosts its power output by increasing the amount of air that enters the combustion chamber. It operates by utilizing exhaust gases to rotate a turbine, which then powers a compressor that pumps more air into the engine cylinders. This increased airflow allows the engine to burn more fuel, resulting in more power and better performance. Turbochargers are commonly used in high-performance vehicles and are a popular aftermarket upgrade for enthusiasts looking to boost their engine's power output.

Why Use a Turbocharger?

Turbocharging is a popular method used by engineers to increase the amount of air that enters an engine's cylinders. This is because it offers several advantages over other methods. For one, it is more efficient and can provide a significant boost in power without adding too much weight or complexity to the engine. Additionally, turbochargers can help improve fuel economy by allowing smaller engines to produce more power when needed, reducing the need for larger, less efficient engines. Overall, turbocharging is a reliable and effective way to improve the performance of an engine.

Turbochargers are a type of forced induction system that increases the power and performance output of an engine by compressing air and allowing for more fuel to be burned. The compressed air is forced into the engine, resulting in a boost in power and acceleration. Turbochargers are commonly used in high-performance vehicles and can significantly improve their acceleration and top speed. This results in a significant increase in torque and horsepower, with some turbocharged engines producing as much power as engines with two additional cylinders. By boosting air pressure by 6 to 8 pounds, a turbocharged engine can see a torque increase of 40% or more, which can translate into as much as 150 additional horsepower.

Turbochargers are becoming increasingly popular in the automotive industry, and for good reason. Take the Ford F-150, for example. A model with a 3.5L EcoBoost V6 engine produces an impressive 375 horsepower, which is only 10 horsepower less than the same truck with a non-turbo 5.0L V8 engine. However, the EcoBoost V6 generates 83 lb.-ft. more torque and has better fuel efficiency, making it a more practical and powerful option for truck enthusiasts.

Turbochargers are becoming increasingly popular in the automotive industry as they allow for smaller and lighter engines to produce the same amount of power as larger engines. This is achieved through the use of direct fuel injection and variable valve timing, which work in conjunction with the turbocharger to meet strict fuel economy and emissions standards. As a result, many automakers are turning to turbochargers to improve the efficiency and performance of their vehicles.

Disadvantages Of Turbocharging

Turbo Lag.

While turbocharging can provide a boost in power and performance, it also comes with some disadvantages. One of the most notable is turbo lag, which occurs when there is a delay between pressing the accelerator and the engine producing the exhaust gases needed to spin the turbo. This delay can be frustrating for drivers who expect immediate power and acceleration.

Complexity:

Another major drawback is the added complexity of installation and maintenance. Unlike traditional engines, turbochargers are connected directly to the exhaust system, requiring additional components such as intake piping, boost controllers, intercoolers, downpipes, knock sensors, and high-capacity fuel pumps. This complexity can make repairs and maintenance more difficult and time-consuming.

Heat:

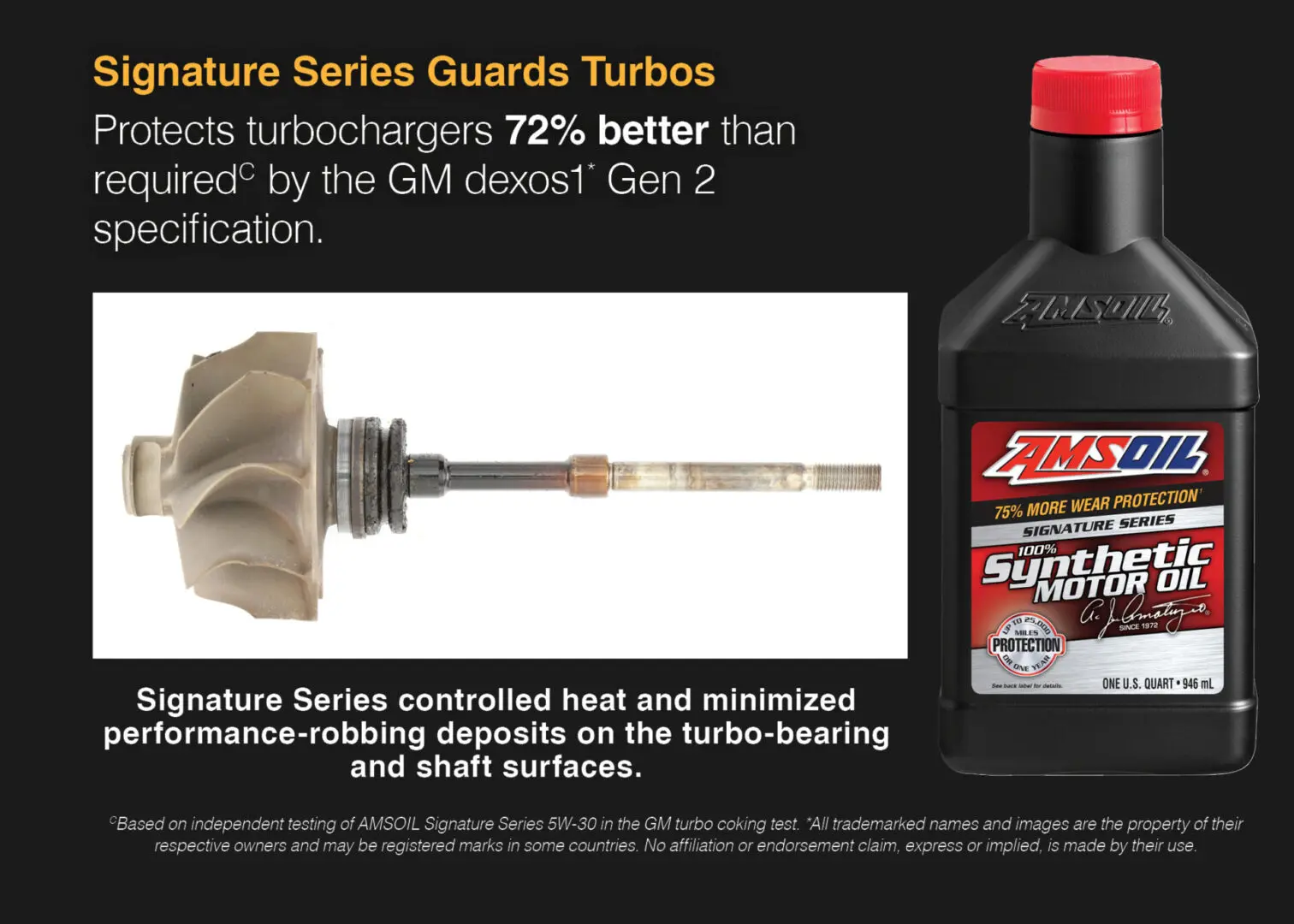

The intense heat generated by the exhaust gases in a turbo can reach temperatures over 1,000ºF and spin the turbine at speeds up to 150,000 rpm. This extreme heat and pressure can cause traditional oils to deteriorate more quickly, leading to potential engine damage.

Lifespan:

The lifespan of a turbocharger is dependent on various factors, including the level of heat and stress it endures. Over time, the lubrication within the turbocharger can break down, leading to the formation of harmful bearing deposits known as turbo coking. This can cause a reduction in performance or even complete failure of the turbocharger. It is important to note that while the average lifespan of a turbocharger is shorter than that of an engine, failure of the turbocharger could potentially cause damage to the engine as well.

Cooldown:

It is important to give a turbocharged engine a cooldown period after running at high speeds. This involves running the engine at low idle for a few minutes, allowing the turbo to cool down before turning off the engine. Failure to do so can result in additional coking and wear on the turbo, which can lead to premature failure. So, make sure to give your engine the proper cooldown it needs to keep it running smoothly.

Fun Fact: Did you know that turbochargers use the exhaust gases from an engine to spin a turbine, which then compresses more air into the engine? This process helps to increase the power and efficiency of the engine, making it a popular choice for high-performance vehicles.

What Is a Supercharger?

A supercharger is a device that increases the amount of air that enters an engine's cylinders, resulting in more power. It achieves this by using power from the engine's crankshaft to run a compressor that forces more air into the cylinders. There are several ways to drive a supercharger, including belt, gear, chain, or direct drive. Some superchargers even use an electric motor instead of mechanical power from the engine.

Why Use a Supercharger?

If you're looking for immediate power delivery and want to eliminate the effects of turbo lag, a supercharger may be the way to go. Unlike turbocharged engines, which still require higher engine speeds to create power, superchargers provide instant boost even at low rpm. While modern turbocharged engines have nearly eliminated turbo lag, a supercharger added to a normally aspirated engine can create more usable power. So, if you're looking for a quick and responsive ride, a supercharger might be the perfect addition to your engine.

Positive Displacement vs. Dynamic

When it comes to superchargers, there are two main types: positive displacement and dynamic. The key difference between the two lies in how they transfer air. Positive displacement superchargers use a fixed amount of air per revolution, while dynamic superchargers adjust the amount of air based on engine speed.

Positive Displacement

Positive displacement superchargers are a type of forced induction system that provide a consistent level of boost pressure to the engine, regardless of its speed. This is achieved using pumps that deliver a fixed volume of air per revolution of the compressor. These superchargers are highly efficient, with some designs reaching up to 50% efficiency at high boost levels. They are particularly effective at generating power at low rpm. Positive displacement superchargers come in several types, including Roots, rotary-screw (Lysholm), sliding vane, and scroll-type.

Dynamic Superchargers

Dynamic superchargers are a type of compressor that can create a significant boost in engine power by accelerating air to high speeds and converting that velocity into pressure. This process can be up to 85% efficient, but it is most effective at higher engine speeds. The two most common types of dynamic compressors are multi-stage axial-flow and variable-ratio centrifugal compressors.

Disadvantages of Supercharging

Bulk:

Supercharging can provide a significant boost in power to an engine, but it also comes with some drawbacks. One major disadvantage is that the size and power requirements of a supercharger can be impractical for smaller engines found in everyday vehicles. As a result, superchargers are typically only installed in high-performance vehicles and hot rods rather than in production vehicles. This can make them less accessible and more expensive for the average driver.

Efficiency:

When it comes to efficiency, superchargers have their drawbacks. While they can boost engine power, they also require some of that power to operate, resulting in a loss of horsepower. This not only makes them less fuel efficient, but also contributes to greater emissions.

Cost:

The cost of a supercharger can vary depending on the vehicle it is custom-built for. As they are not commonly included in new vehicles and are not mass-produced, they can be difficult to acquire and come with a higher upfront cost. Additionally, replacement parts for superchargers can also be expensive.

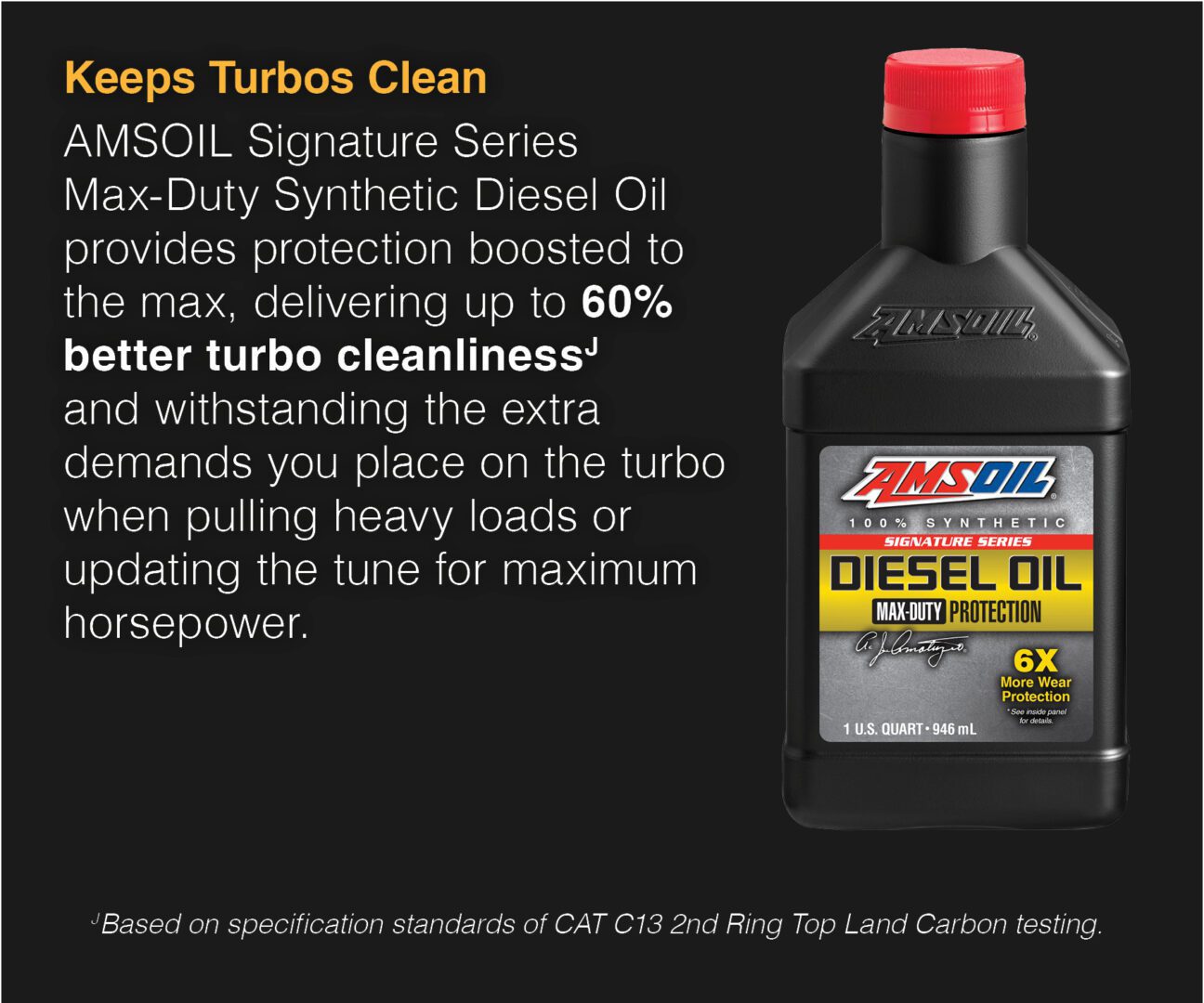

What Good Is Added Performance If You Don't Protect Your Engine?

When you add more power to your engine, it also generates more heat, which can lead to engine wear and reduced efficiency. This is especially true for turbocharged engines. However, using synthetic motor oil can increase your engine's heat resistance and keep it cooler, reducing the risk of oil breakdown and harmful deposits that can cause early wear. In fact, AMSOIL Signature Series Synthetic Motor Oil has been proven to protect against engine wear and deposits on turbochargers 4 times better than the leading competitor in industry-standard testing. And for turbo diesel engines, AMSOIL Signature Series Max-Duty Synthetic Diesel Oil can deliver up to 60% better cleanliness. So, while added performance is great, protecting your engine is just as important for its longevity and efficiency.