ASTM D5800: The Standard Behind the Noack Volatility Test

What Is ASTM D5800?

ASTM D5800 is the official laboratory procedure for measuring oil volatility using what's known as the Noack Volatility Test. Developed originally in Europe and standardized by ASTM International, this test evaluates an oil's tendency to evaporate under high temperatures. The result is expressed as a percentage of mass lost due to evaporation. Lower numbers mean more stable oil and better engine protection.

Today, ASTM D5800 is a required component of nearly all major engine oil specifications, including:

-

API SP

-

ILSAC GF-6A / GF-6B

-

GM dexos1™ Gen 2

-

ACEA C5 / A5 / B5

-

Ford WSS-M2C946-A

Why Oil Volatility Matters

Volatility isn't just a lab metric—it directly impacts your engine. High volatility oils tend to "boil off" under heat, reducing the oil volume and its ability to protect critical components. This leads to increased oil consumption, deposits, poor fuel economy, and more wear.

Modern engines make this even more important. Turbochargers, gasoline direct injection (GDI), and idle-stop systems run hotter and demand lubricants that resist evaporation under extreme conditions.

How the ASTM D5800 Noack Volatility Test Works

The ASTM D5800 procedure, commonly known as the Noack Volatility Test, simulates the intense heat conditions found inside modern engines to measure how much motor oil evaporates under stress.

Here’s how it works:

-

A sample of engine oil is precisely weighed.

-

The sample is heated to 250°C (482°F) for one hour.

-

During this time, dry air flows across the surface to replicate airflow and combustion heat.

-

As lighter oil molecules evaporate, they are collected separately.

-

After testing, the remaining oil is re-weighed.

-

The difference in mass is expressed as a percentage of weight loss — this is the oil’s volatility score.

What the Result Means:

-

A lower percentage indicates lower volatility and better thermal stability.

-

Oils with less than 10% mass loss are considered highly stable.

-

To meet industry standards, oils must stay below specific thresholds:

-

API SP / ILSAC GF-6: ≤15%

-

GM dexos1™ Gen 2: ≤13%

-

For example, an oil showing 10% volatility means 10% of its original mass evaporated under test conditions. This result directly affects how well the oil resists thinning, consumption, and breakdown in high-heat environments.

Why the Test Exists

Before ASTM D5800, oil volatility was assessed using rough estimates like flash point or visual signs of oil loss. But those methods were inconsistent.

The Noack Volatility Test (now formalized as ASTM D5800) was developed to:

-

Accurately simulate real-world engine conditions

-

Establish a repeatable, scientific method

-

Set an industry-wide standard for oil formulation limits

Today, ASTM D5800 is cited directly in:

-

API SP and older classifications (SN, SM, etc.)

-

ILSAC GF-6A/GF-6B fuel economy oils

-

OEM specs like GM dexos1™ Gen 2 and Ford WSS-M2C945-B1

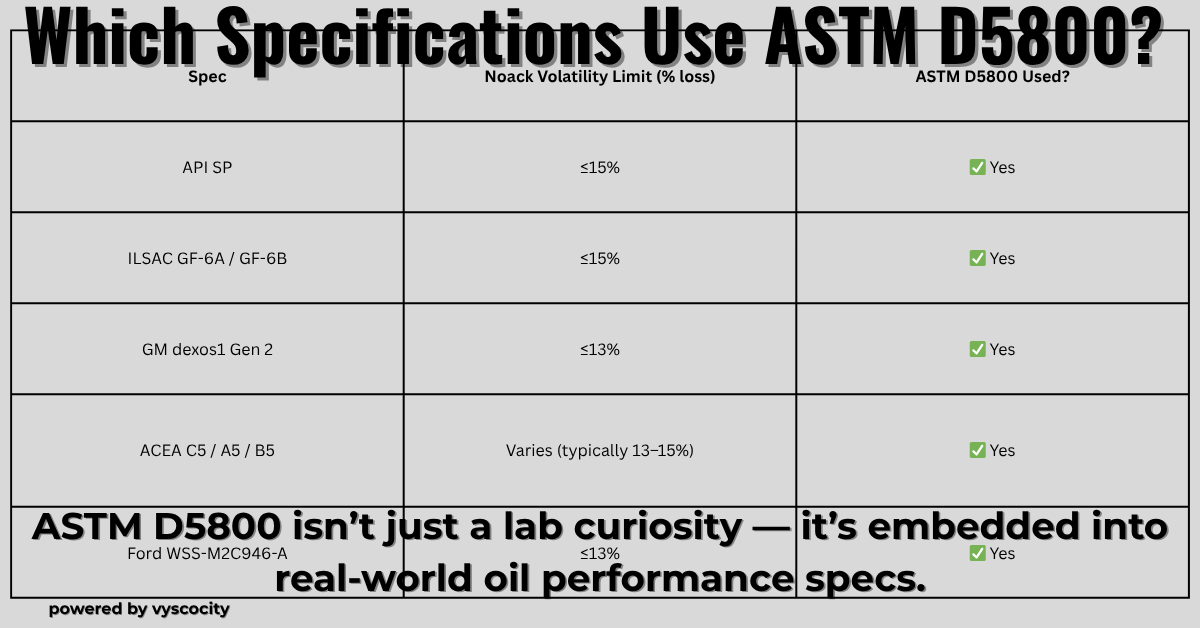

Industry Volatility Limits: What the Specs Say

To control volatility across the board, modern oil specs include maximum Noack values:| Spec | Noack Volatility Limit (% loss) | ASTM D5800 Used? |

|---|---|---|

| API SP | ≤15% | ✅ Yes |

| ILSAC GF-6A / GF-6B | ≤15% | ✅ Yes |

| GM dexos1 Gen 2 | ≤13% | ✅ Yes |

| ACEA C5 / A5 / B5 | Varies (typically 13–15%) | ✅ Yes |

| Ford WSS-M2C946-A | ≤13% | ✅ Yes |

History: AMSOIL's Early Use of ASTM D5800

AMSOIL was the first oil manufacturer in North America to apply the Noack Volatility Test to its products back in 1985—long before it was required by any engine oil spec. Founder Al Amatuzio saw early on that flash point testing wasn't enough. Real-world thermal conditions needed a more reliable benchmark, and ASTM D5800 delivered just that.

Real-World Impact of High Volatility Oils

When engine oils evaporate too easily, it leads to:

-

Frequent top-offs

-

Thicker, degraded oil left behind

-

Unbalanced additive concentrations

-

Increased engine deposits

-

Loss of fuel economy

Drivers may notice symptoms like more smoke, harder cold starts, or even knocking. This isn't always a mechanical issue – it's often volatility at play.

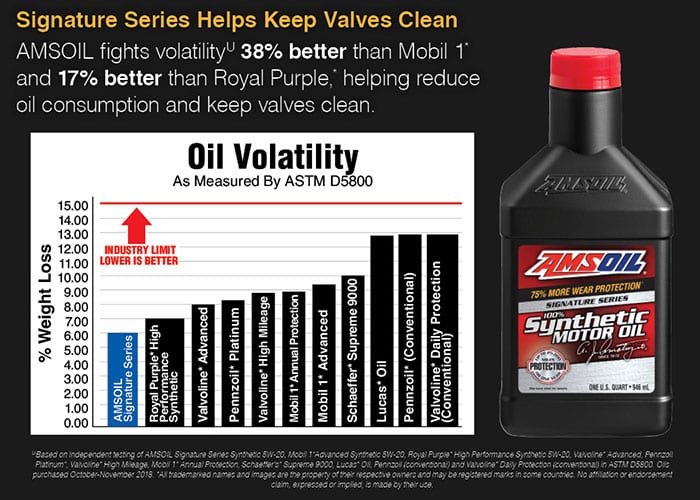

How AMSOIL Performs in ASTM D5800 Testing

AMSOIL synthetic motor oils, especially Signature Series, consistently show Noack volatility results of 6–8%. That's far below the maximum thresholds and often half the volatility of many conventional and even synthetic competitors.

By contrast, oils like Mobil 1 Extended Performance often hover near 12–14%, just below the spec limit. That may be acceptable on paper, but in harsh real-world use – especially towing, high-speed driving, or turbo applications – AMSOIL's lower volatility translates to real protection.

This means:

-

Less evaporation under heat

-

More stable vyscocity

-

Additives stay balanced

-

Longer protection between changes

-

Improved cold starts and fuel efficiency

In contrast, many competing synthetics (including Mobil 1, Castrol Edge, and Pennzoil Platinum) hover closer to the 11–14% range, just inside the spec. AMSOIL doesn't just meet the line — it sets the bar.

Thermal Stability = Longevity

ASTM D5800 results aren't just a number. Lower volatility means:

-

Longer oil life

-

Less consumption

-

Lower emissions

-

Cleaner engines

It's also a core reason AMSOIL can recommend extended drain intervals up to 25,000 miles under normal service.

Who Should Care About ASTM D5800 Results?

Volatility affects everyone, but especially:

-

Turbo owners (gas and diesel)

-

Towing and heavy load drivers

-

Hot climate vehicles

-

Stop-and-go commuters

-

Fleet managers watching oil usage and maintenance costs

-

DIYers who notice frequent oil top-offs

If you're any of the above, ASTM D5800 isn't just lab trivia — it's directly tied to how your oil performs when you need it most.

🔗 Related Pages

How to Find D5800 Data on an Oil Product

Not every brand publishes its Noack result. AMSOIL does.

Look for:

-

TDS (Technical Data Sheet) or PDS (Product Data Sheet)

-

A line that says “NOACK Volatility (% loss)”

-

The method should state: ASTM D5800

If a brand doesn't publish this data — it may be worth asking why.

Modern Engines Make Volatility a Bigger Problem

Today's engines run hotter and harder than ever. Consider:

-

Turbochargers often operate at 800–1,000°F

-

GDI engines run hotter in the combustion chamber

-

Start-stop systems create more idle heat cycles

-

Fuel economy demands push oils thinner (0W-20, 0W-16)

All of this means: if your oil boils off easily, you're at risk.

That's why low Noack volatility is not optional — it's now a baseline requirement in nearly every modern engine oil certification.

ASTM vs API vs OEM Specs: What's the Difference?

-

ASTM = the test method (e.g., D5800 for volatility, D445 for viscosity)

-

API/ILSAC/dexos/etc. = the performance standard (e.g., API SP)

-

The standard says: “To pass, your oil must lose no more than 15% weight in ASTM D5800.”

Think of ASTM like a ruler — it doesn't say how long something should be, just how to measure it.

Why Evaporative Loss Matters

High volatility = high oil loss. That means:

-

More frequent top-offs between oil changes

-

Thicker vyscocity as light molecules evaporate

-

Unbalanced additives (what's left behind isn't what you poured in)

-

Poor protection during cold starts

-

Increased deposits and carbon buildup

-

Turbocharger stress from reduced oil volume

In other words, oil with high volatility doesn't just evaporate — it fails under pressure.

Why ASTM D5800 Matters for You

This test may seem like an obscure lab procedure, but it tells you exactly how well your oil holds up to heat. When paired with synthetic base stocks and robust formulations like AMSOIL's, low volatility ensures your engine stays cleaner, better protected, and more efficient. Whether you're pulling a trailer, idling in traffic, or just aiming to extend oil change intervals—ASTM D5800 is a test worth knowing.

Where to Buy / Become a Dealer

Looking to buy AMSOIL?

Powered by Vyscocity

Built by Vyscocity to help you get the job done right — whether you're riding, wrenching, or running a fleet.

Explore our products, try our free tools, and let us know how it works for you.

❓ Still stuck? Ask your question on Facebook →

No fluff. Just function.